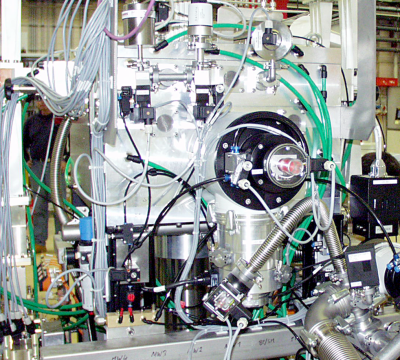

W&L镀膜系统公司专精于将实验室小型设备的成熟工艺升级为量产化生产平台。

我们始终专注于真空工艺的特殊需求,依托长期合作的优质合作伙伴与顶级零部件供应商,打造高可靠性、高效益的生产系统。

我们的专业团队不仅能将客户需求转化为切实可行的解决方案,更能全程协助客户熟练掌握W&L镀膜系统的产品应用。

我们的核心竞争力

W&L镀膜系统的核心技术基于两大真空镀膜工艺:

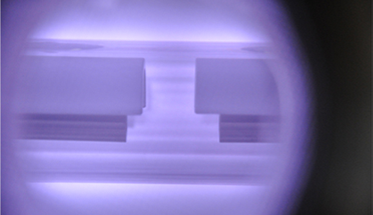

- 物理气相沉积(PVD)技术 我们主推磁控溅射镀膜技术,该技术通过叠加静磁场与静电场(或振荡电场)来维持高密度等离子体放电。在真空环境下,利用等离子体轰击固态金属或陶瓷靶材,使其原子溅射沉积,从而在大型基材表面形成超薄的金属或陶瓷薄膜层。

- 等离子体增强化学气相沉积(PECVD)技术 将气化的成膜前驱体材料与非成膜气体混合后,置于真空腔室中,在适当压力下施加微波等能量源激发等离子体放电。通过复杂的等离子体化学反应,可制备出有机薄膜、陶瓷薄膜以及晶体薄膜等多种功能性镀层。

新闻

18.08.2025诚邀莅临法兰克福ACHEMA展会

我们将于2024年6月10日至14日,在法兰克福ACHEMA 2024展会上展示全新研发的创新型硼掺杂金刚石电极及电解槽废水处理技术。欢迎莅临11.0馆C77展位参观交流。

18.08.2025磁控溅射PVD技术

此技术采用特殊排布的永磁体产生磁场,在待溅射靶材表面附近,通过电能或电磁能激发形成特定形态的等离子体放电。通常,溅射等离子体放电会形成所谓的闭合跑道形状。等离子体中的氩离子被加速轰击靶材,产生靶材物质的蒸汽,这些蒸汽将在基板上冷凝形成薄膜。

采用等离子体增强化学气相沉积(PECVD)和物理气相沉积(PVD)技术实现产品升级

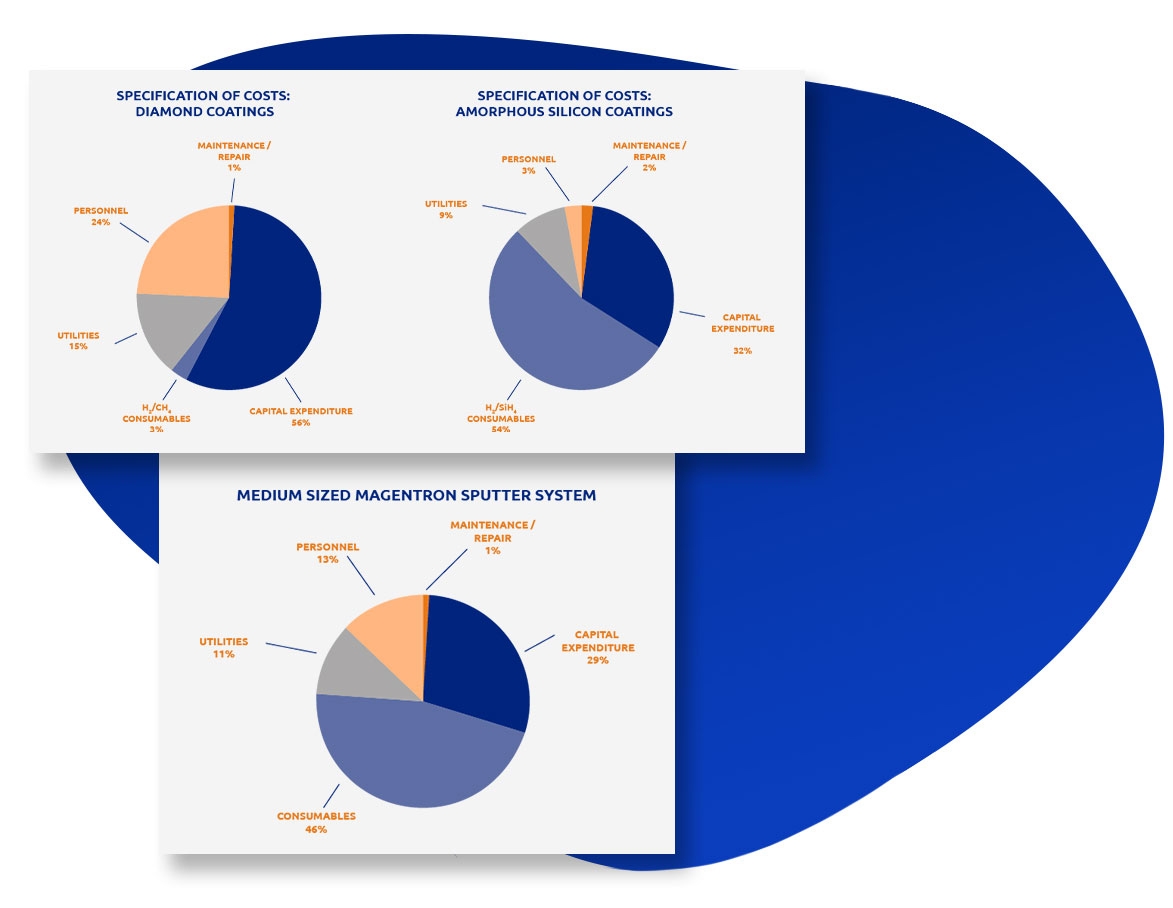

通过PECVD工艺制备的金刚石薄膜(无论是纯净型还是导电型)具有独特性能,可满足多种应用需求。作为终极生物相容材料,可用于医疗植入体表面镀膜。掺硼金刚石镀膜电极是去除废水中有毒化学物质的首选,并可在水性环境中制备臭氧。通过PVD工艺将贵金属薄膜沉积在廉价基材上,可以提供贵金属所需的表面特性,又无需承担基材的高昂成本。

真空镀膜技术以适中成本显著提升材料表面功能性