W&L Coating Systems excels in upscaling of processes developed on small scale laboratory type systems into production ready platforms.

A clear focus on the special needs of vacuum processes combined with a long-standing base of partner companies and suppliers of top quality components are the foundation of highly reliable and profitable production systems.

A team of qualified specialists not only converts the desires and requirements of customers into working solutions but also assists and supports customers becoming familiar with the products of W&L Coating Systems.

Our competencies

The business model of W&L Coating System rests on two very different vacuum based technologies

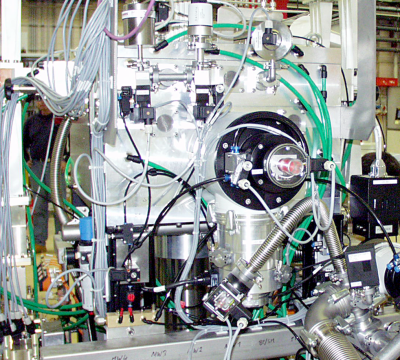

- Physical Vapour Deposition (PVD). The preferred method is called magnetron sputtering where dense plasma discharges are maintained by superimposed static magnetic and static or oscillating electric fields. Extremely thin metallic and ceramic films on large surfaces are produced by plasma erosion of solid metallic or ceramic targets.

- Plasma Enhanced Chemical Vapour Deposition (PECVD). Film forming vaporized or gaseous pre-cursor material joined by non film forming gases are subjected to a power source such as microwave power in a vacuum chamber at a suitable pressure to form a plasma discharge. Organic, ceramic and crystalline thin films are produced by complex plasma chemistry processes.

We will be presenting our new and competitve boron doped diamond electrode and cell technology for wastewater treatment at the ACHEMA 2024 in Frankfurt from 10th to 14th of June. Please visit our booth C77 in Hall 11.0.

Planar arrays of variable numbers of linear plasma sources in parallel arrangements powered by microwaves are the preferred approach for large scale production of thin films like nano crystalline diamond

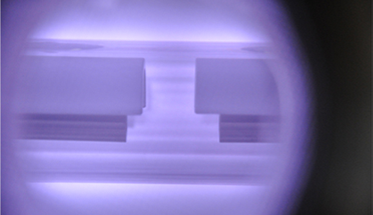

Usually this system platform consists of a number of aluminium frames and flanges with built in water cooling which carry process gas supply pipes, the plasma source array, the substrate carrier unit and vacuum pumping ports.

Magnetic fields by permanent magnets in a special arrangement define the shape of plasma discharges powered by electric or electromagnetic power close to target surfaces to be sputtered. Usually, sputter plasma discharges have the shape of so called closed race tracks. Argon ions from the plasma are accelerated towards the target to create a vapor of target material which will condense and form thin films on substrates.

Product enhancement by plasma enhanced chemical vapor deposition (PECVD) and physical vapor deposition (PVD)

Diamond thin films –pristine or electrically conductive – produced by PECVD processes display unique properties and can be used for a variety of products or purposes. As ultimate bio-compatible material diamond films can cover the surfaces of implants. Boron doped diamond coated electrodes are first choice for removing toxic chemical compounds in wastewater and can be used to produce ozone in aqueous environment. Thin precious metal films deposited on inexpensive solids by PVD processes provide desired surface properties of such precious metals without having to bear significant costs of solids.

Vacuum based thin film deposition offer enhanced functionality of surfaces at moderate costs

The economy of vacuum processes

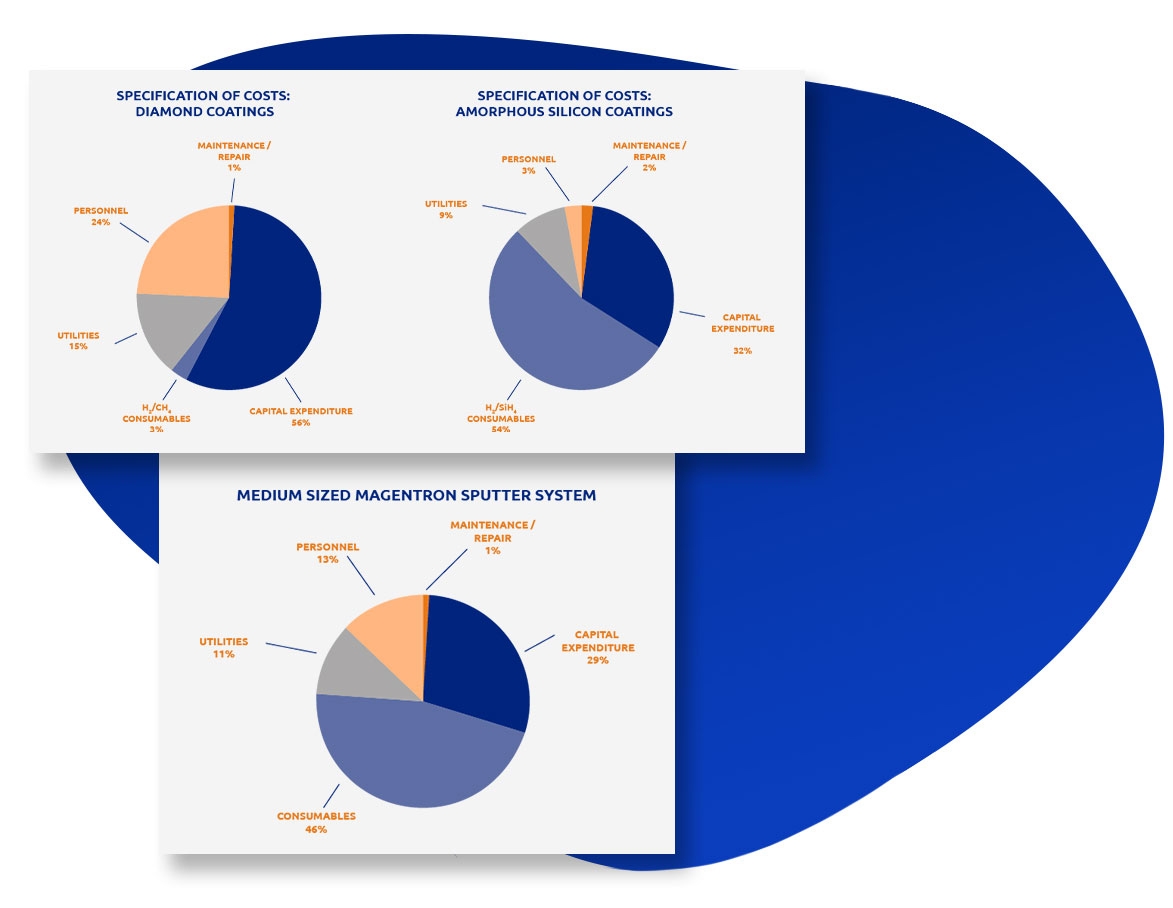

The cost of ownership and production costs are usually divided into depreciation and rent, utilities, personnel and consumables. It is still widespread belief that huge investment levels for vacuum based process technology makes it appear too expensive for mass production. Detailed cost assessments show, however, that the costs for consumables or even utilities may exceed depreciation costs significantly.

Vacuum process technology offers unique features at reasonable costs

Leading in advancement and up-scaling of PECVD and PVD technology

The main innovative strength of the company manifests primarily in the transfer of laboratory scale processes to industrial production and in methods to reduce costs by increasing efficiency or reduced consumption of precursor material.