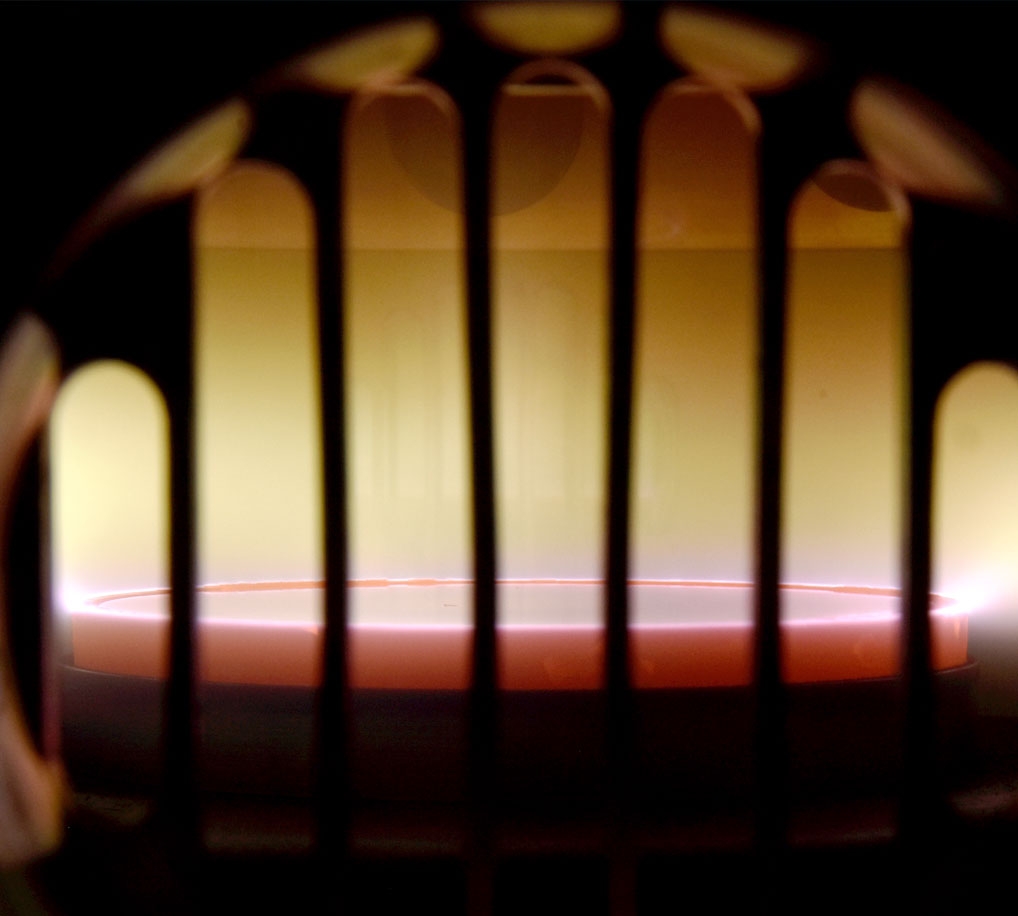

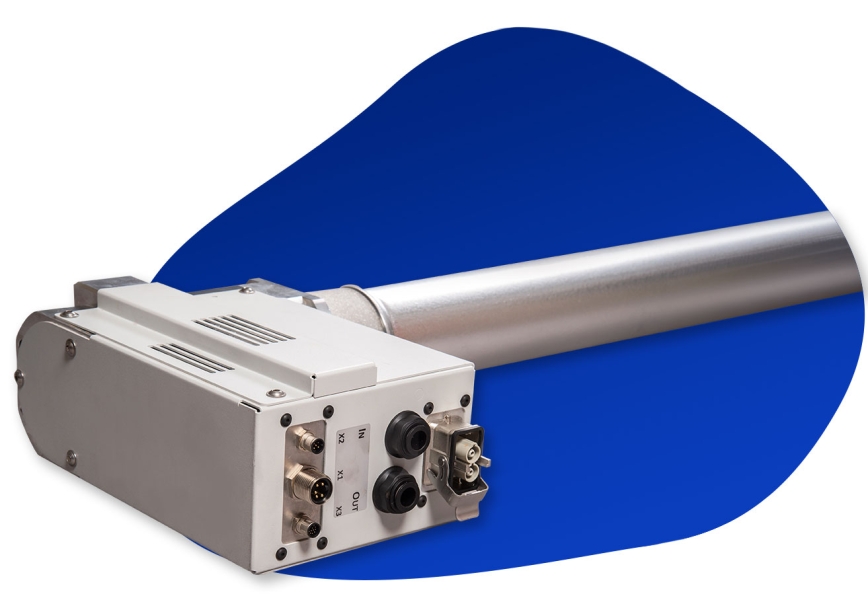

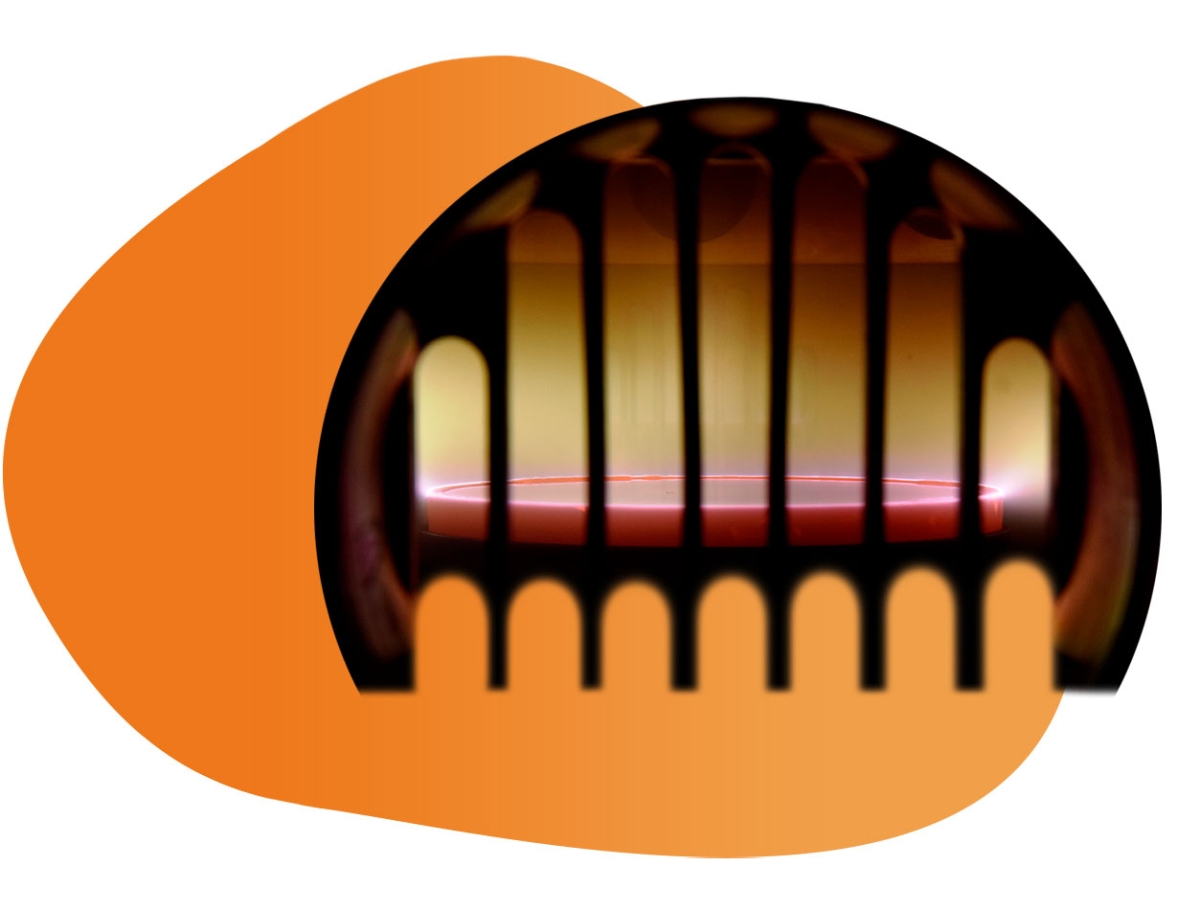

15 kilowatts of microwave power sustaining a hydrogen-methane plasma which is capable of heating a molybdenum substrate carrier plate to a 1,000°C and more need adequate water cooling.

But the microwave transmission line with the impedance matched transition from rectangular waveguide to a coaxial line also requires efficient water cooling.

A total of 6 optical viewports enable visual access to the plasma discharge in the center – not only for visual inspection but also for an infrared camera which helps to control thermal equilibrium across the 4 inch substrates.

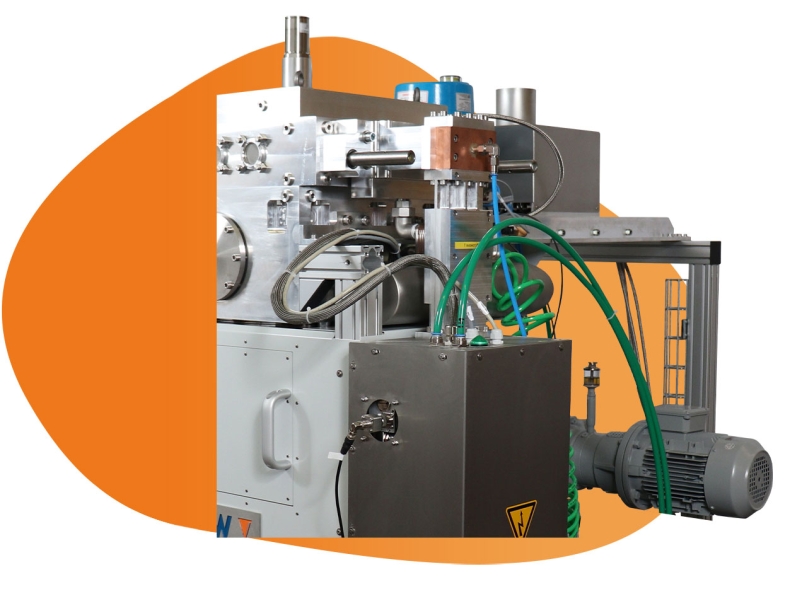

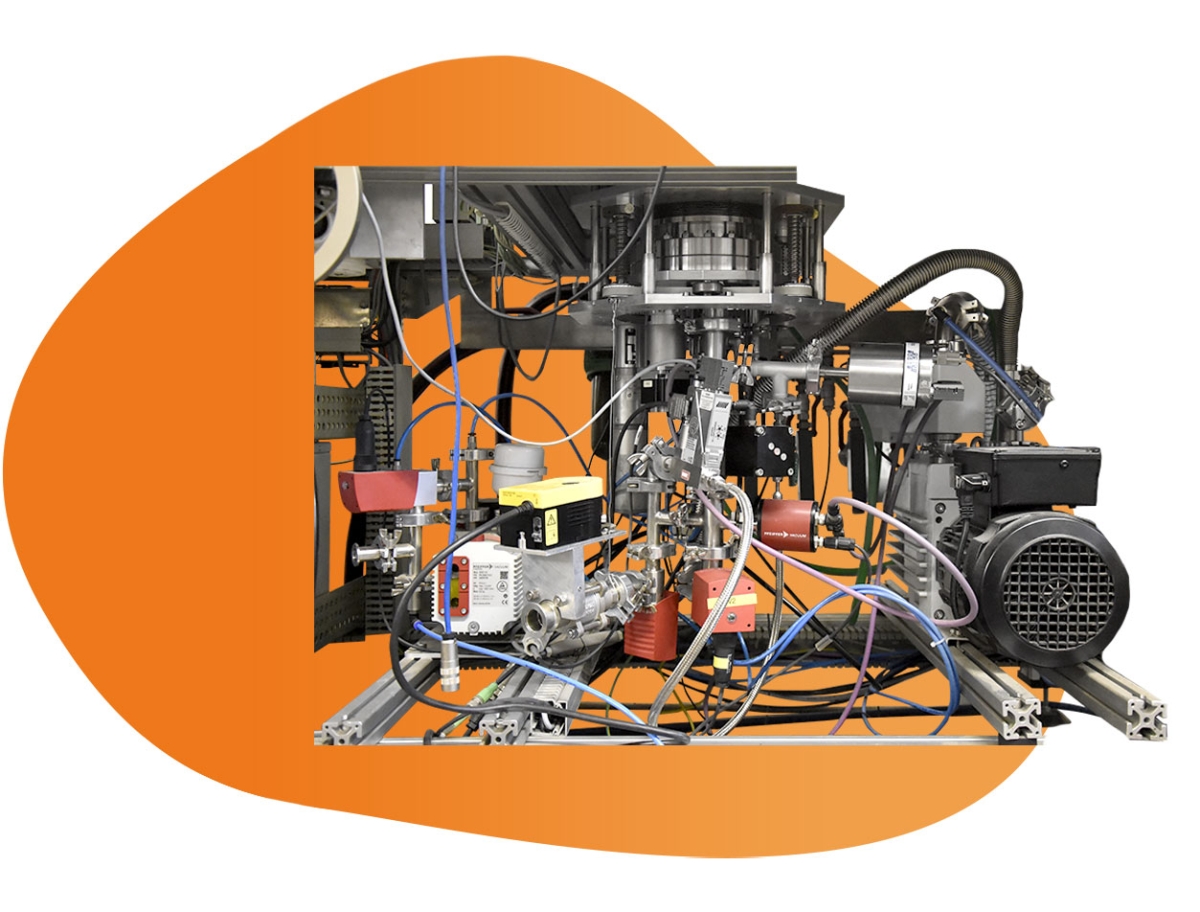

The substrate stage

The entire substrate stage is motor driven and PLC controlled for adjusting the distance between substrates and the CBR microwave launcher. In addition to the main substrate height adjustment which may be sufficient for the uniform growth of microcrystalline diamond layers a much more precise secondary height adjustment system for single crystal growth is available within the main stage.

It allows selected areas of the 4 inch stage to be lowered at the deposition rate. It can be set to rates of micrometers per hour to make sure the growing surface of single crystal diamonds will remain under constant plasma properties over extended periods of time.

Automation

The CBR system is fully automated by a Siemens PLC and a suitable human computer interface for remote operation. The growth of single crystal diamonds can last as long as 2 weeks. The light intensity of the plasma discharge can be monitored very precisely and can be used to switch off the system should a plasma breakdown or any other unforeseen malfunction happen.

The hydrogen-methane plasma for the growth of micro crystalline diamond layers

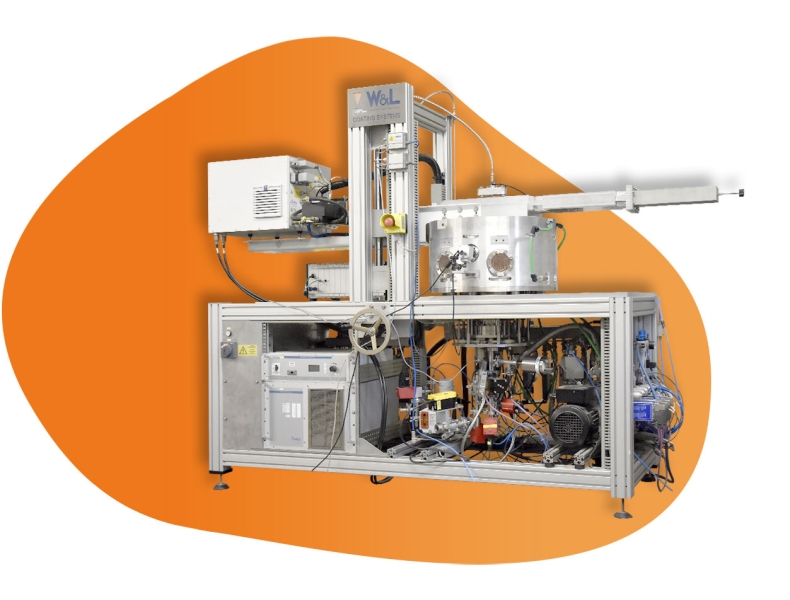

The CBR system has been designed for homogeneous plasma enhanced chemical vapour deposition of single crystal diamond and micro crystalline diamond layers across a 4 inch deposition area employing 2.45 GHz microwave power rather than 915 MHz and competitive cost of ownership

CBR

A system for diamond production in a vacuum plasma environment