Only vacuum based PECVD processes can compose layers of materials that would not be possible at ambient conditions

Plasma Enhanced Chemical Vapour Deposition by Microwave Power

Industrial PECVD processes in a vacuum environment can be sustained by electric or electromagnetic power ranging from pure DC to microwaves. The higher the frequency of the supplied power the higher the plasma density and the faster the processes. However, maintaining a good process uniformity over large areas becomes increasingly difficult with higher frequencies.

Industrial PECVD processes in a vacuum environment can be sustained by electric or electromagnetic power ranging from pure DC to microwaves. The higher the frequency of the supplied power the higher the plasma density and the faster the processes. However, maintaining a good process uniformity over large areas becomes increasingly difficult with higher frequencies.

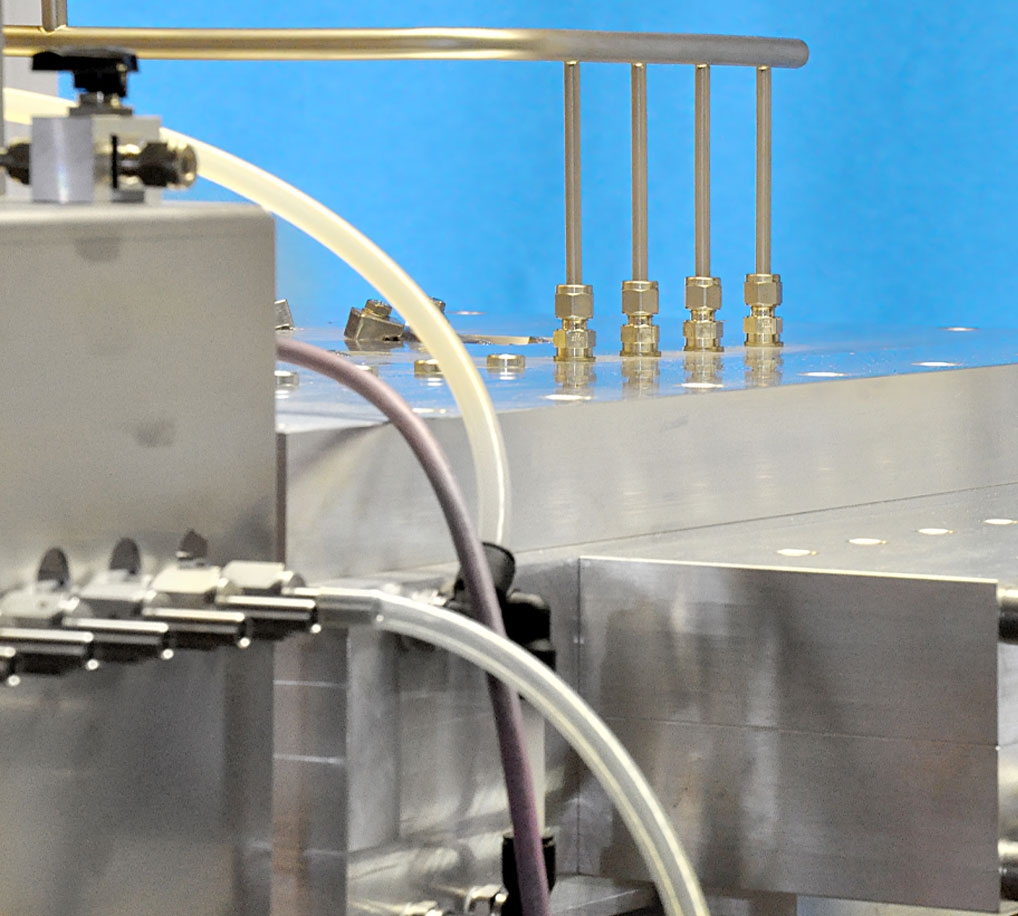

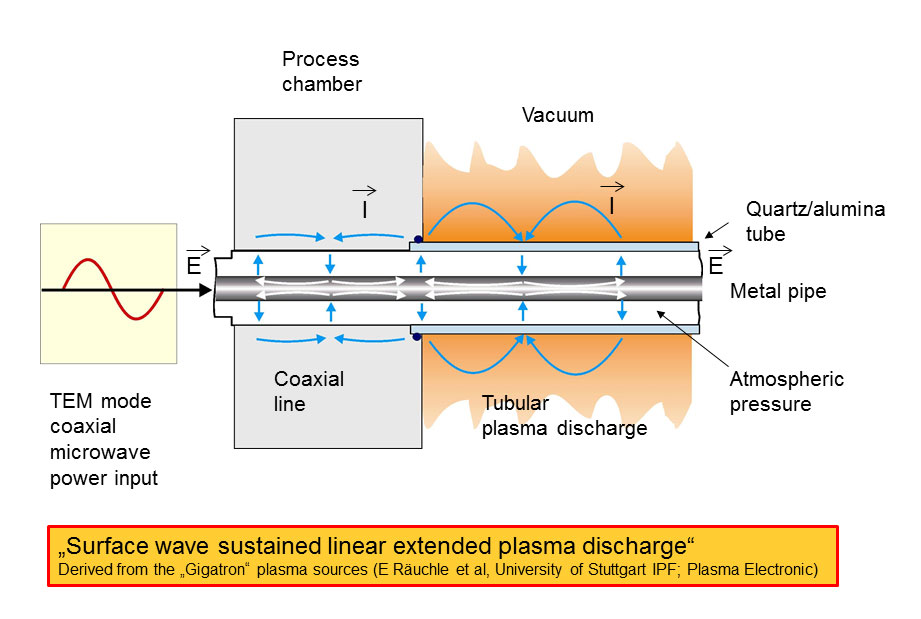

A unique development by researchers at the University of Stuttgart in Germany has overcome this drawback. Uniform plasma discharges over large areas (up to square meters) can be accomplished by arrays of coaxial plasma lines in a parallel arrangement. Microwave power as transversal electromagnetic waves (TEM) propagating along a purely metallic coaxial line are injected into a evacuated vessel at a suitable pressure in which only the outer conductor of the coaxial transmission line has been replaced by a dielectric tube made from refractory dielectric material such as fused silica or alumina. Microwave power will pass through the dielectric tube and ignite a plasma discharge close to the entire outer surface of the tube. The circumjacent plasma can excite and ionize the gas phase and serves as a replacement outer coaxial conductor of a high attenuation coefficient. Thus, steady linear plasma discharges in the range of 1,000 mm and more enable uniform plasma enhanced chemical vapour deposition over large areas.

Organically Modified Ceramic Coatings

Low pressure vacuum based PECVD processes can be used to deposit crystalline, organic, ceramic and organically modified ceramic coatings on many types of substrates from organic precursor material.

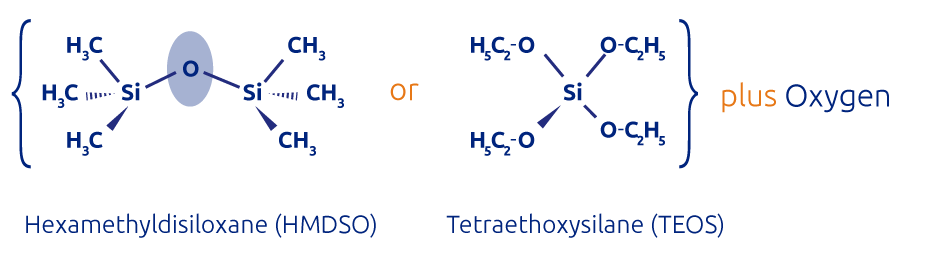

As an example, liquid chemical compounds such as Hexamethyldisiloxane (HMDSO) or Tetraethoxysilane (TEOS) can be vapourised and introduced to a vacuum process reactor together with a sufficient amount of oxygen gas. At the right conditions microwave power turns this gas/vapour mixture into a plasma discharge which may produce pure quartz layers on substrates at rates as high as 1 micrometer per second.

As an example, liquid chemical compounds such as Hexamethyldisiloxane (HMDSO) or Tetraethoxysilane (TEOS) can be vapourised and introduced to a vacuum process reactor together with a sufficient amount of oxygen gas. At the right conditions microwave power turns this gas/vapour mixture into a plasma discharge which may produce pure quartz layers on substrates at rates as high as 1 micrometer per second.

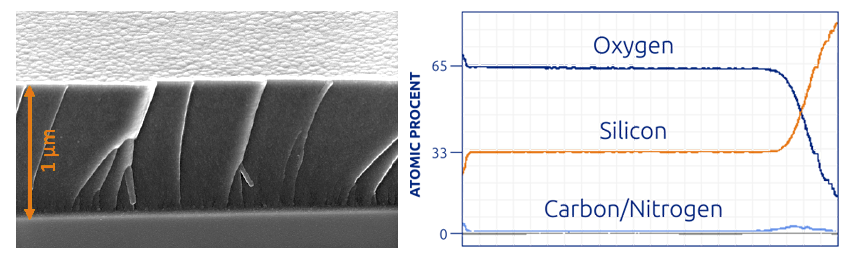

The oxygen rich plasma discharge oxidises and removes all organic chemical ingredients such as carbon and hydrogen from the silicon oxygen backbone of HMDSO resulting in quartz layers of natural stoichiometry as x-ray photoelectron spectroscopy (XPS) depth profile confirms. Such hard but brittle layers can harden soft substrate surfaces like polymers and make them scratch resistant.

The oxygen rich plasma discharge oxidises and removes all organic chemical ingredients such as carbon and hydrogen from the silicon oxygen backbone of HMDSO resulting in quartz layers of natural stoichiometry as x-ray photoelectron spectroscopy (XPS) depth profile confirms. Such hard but brittle layers can harden soft substrate surfaces like polymers and make them scratch resistant.

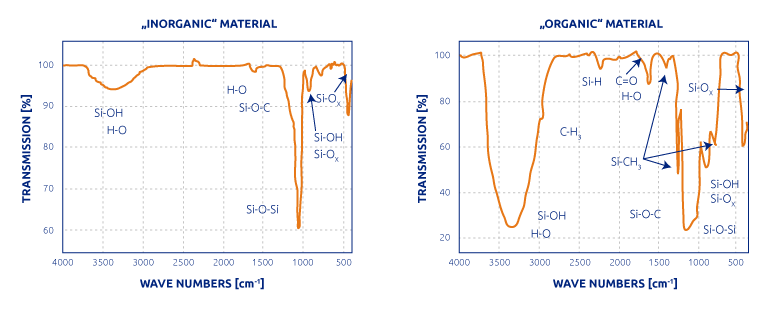

As long as oxygen is abundant for the amount of HMDSO in the plasma discharge quartz layers will be hard and brittle but if there was not enough oxygen available in the plasma to remove and oxidize all remaining organic groups from HMDSO molecules, the deposited quartz layer would show different properties. Even small amounts of carbon in a quartz layer would make it flexural while keeping its scratch resistant surface. Fourier Transformation Infrared Spectroscopy (FT-IR) shows variations of “organically modified” quartz (ceramic). Low pressure vacuum plasma enhanced chemical vapour deposition is a very versatile method for producing thin films with unusual properties.

As long as oxygen is abundant for the amount of HMDSO in the plasma discharge quartz layers will be hard and brittle but if there was not enough oxygen available in the plasma to remove and oxidize all remaining organic groups from HMDSO molecules, the deposited quartz layer would show different properties. Even small amounts of carbon in a quartz layer would make it flexural while keeping its scratch resistant surface. Fourier Transformation Infrared Spectroscopy (FT-IR) shows variations of “organically modified” quartz (ceramic). Low pressure vacuum plasma enhanced chemical vapour deposition is a very versatile method for producing thin films with unusual properties.

Diamond Layers by Microwave Plasma Enhanced Chemical Vapour Deposition

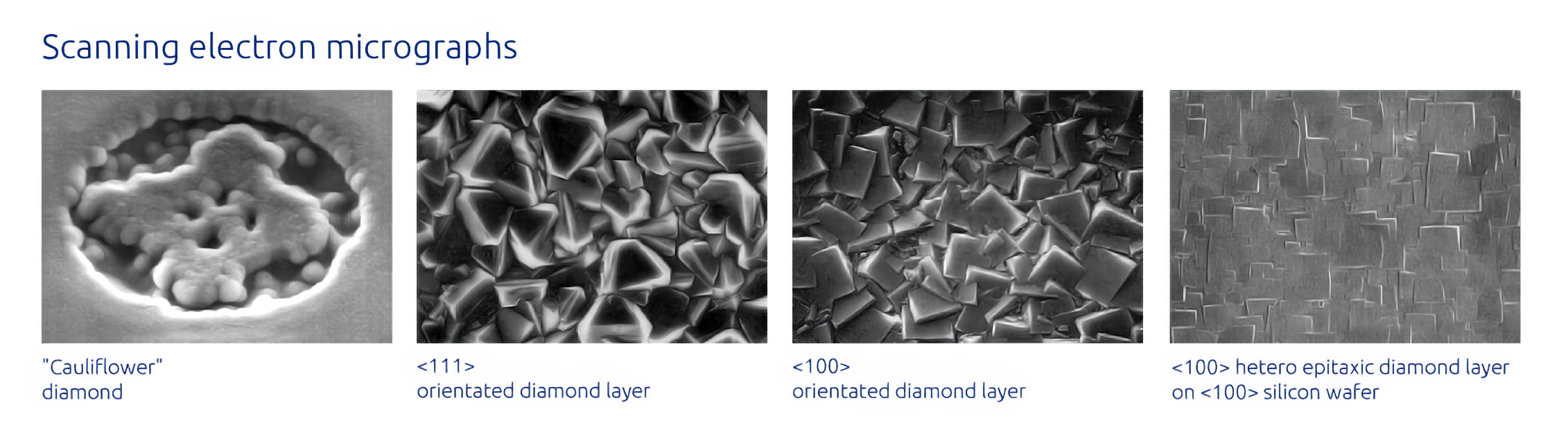

Looking at the phase diagram of carbon, diamond should not be produced in a vacuum system. But as a matter of fact, diamond does grow in different morphologies in vacuum systems. Propelled either by thermal or plasma activation organic carbon precursors such as methane can be transformed into polycrystalline diamond layers or even single crystal diamonds of considerable sizes. Microwave PECVD in particular proved to be a very versatile method to control the layer morphology. Whether carbon atoms turn into cauliflower diamond growth, triangular <111> or rectangular <100> faced polycrystals is controlled by plasma process conditions. Even heteroepitaxial growth of polycrystalline diamond on a single crystal substrate is largely controlled by plasma parameters.

Looking at the phase diagram of carbon, diamond should not be produced in a vacuum system. But as a matter of fact, diamond does grow in different morphologies in vacuum systems. Propelled either by thermal or plasma activation organic carbon precursors such as methane can be transformed into polycrystalline diamond layers or even single crystal diamonds of considerable sizes. Microwave PECVD in particular proved to be a very versatile method to control the layer morphology. Whether carbon atoms turn into cauliflower diamond growth, triangular <111> or rectangular <100> faced polycrystals is controlled by plasma process conditions. Even heteroepitaxial growth of polycrystalline diamond on a single crystal substrate is largely controlled by plasma parameters.