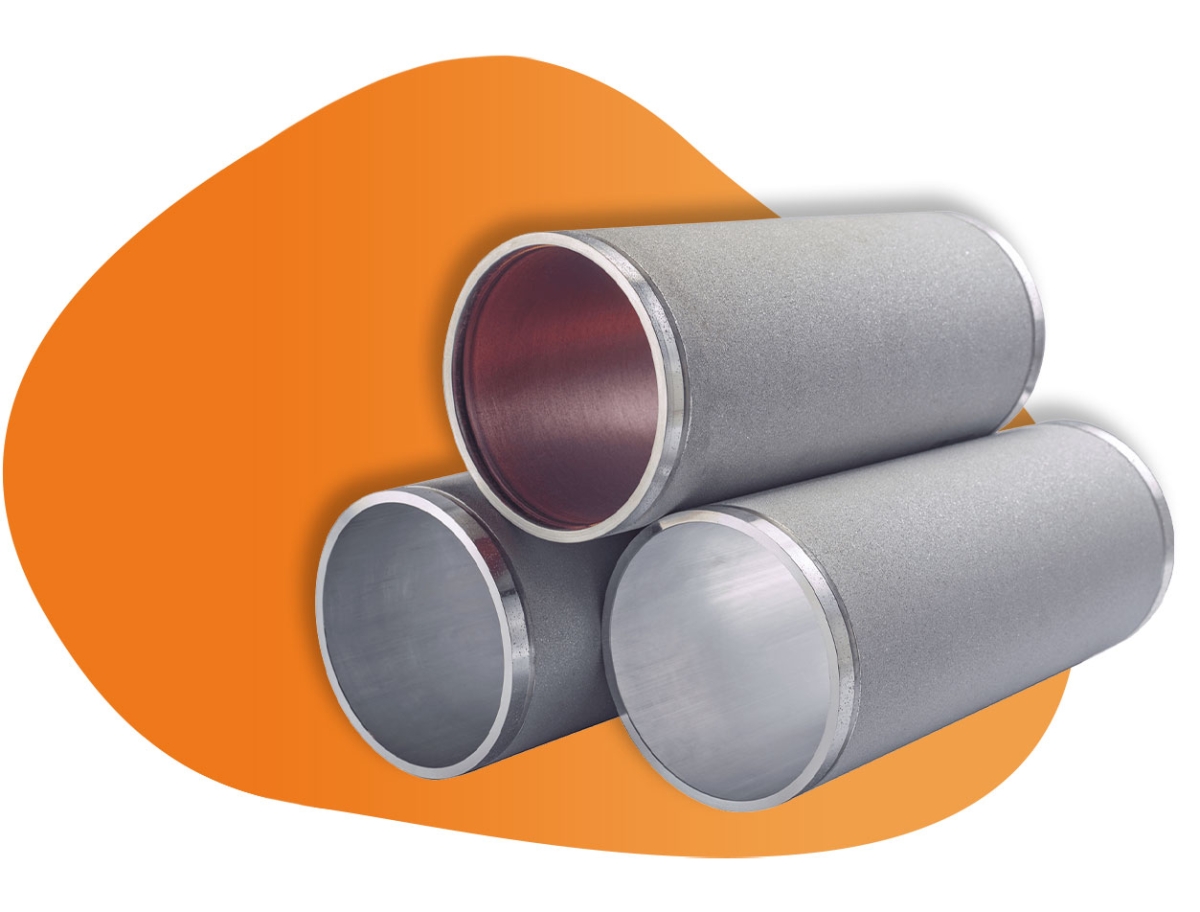

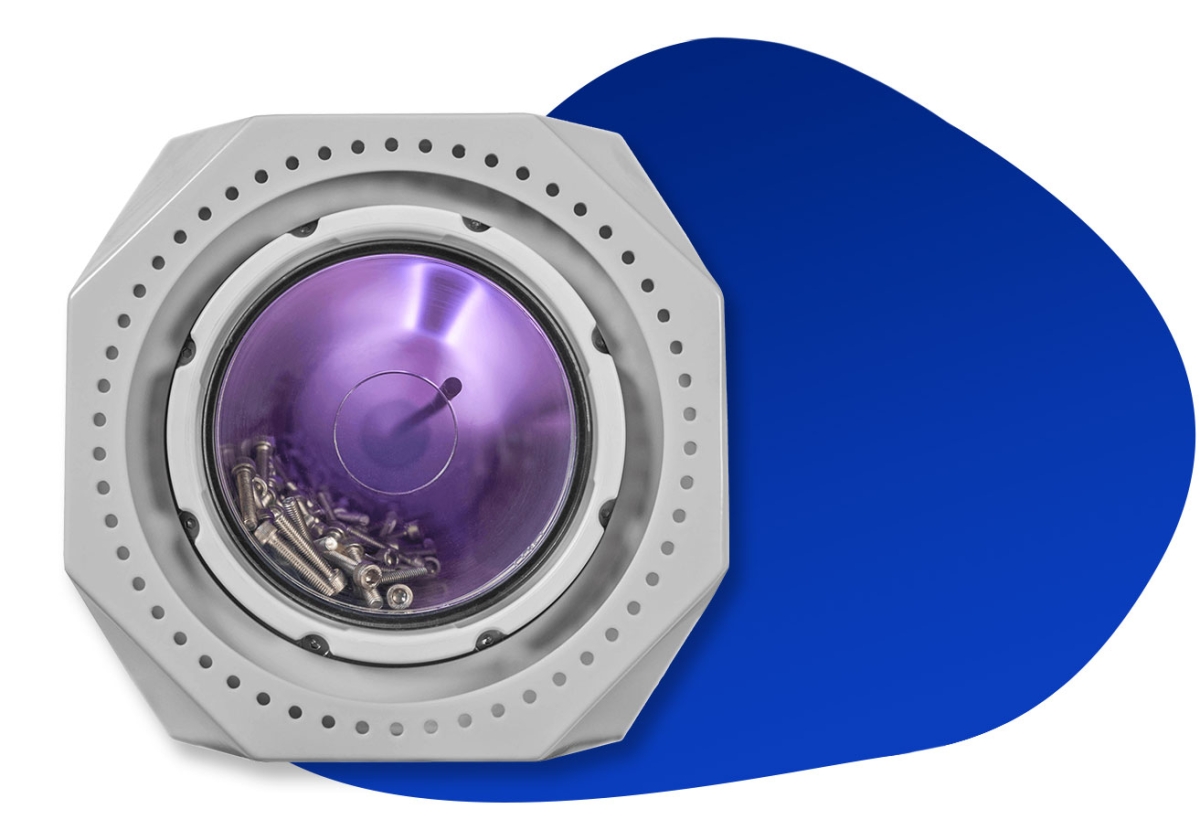

The special, cylindrical target design of the systems ensures that the sputtered material that is not deposited on the substrates returns to the sputter target and is therefore immediately available for further coating.

The sputtered material that is not redeposited onto the sputtering target is absorbed by the systems comparatively small, front-side copper shields, which can be easily recycled. In this way, material utilization is maximized and the loss of valuable material is reduced to zero - in contrast to conventional sputtering systems.

• Economical, high-quality coatings of complex, three-dimensional objects

• Highly productive batch coating system

• No loss of valuable sputtering target materials

• Environmentally friendly

• Quick and easy exchange of the target material

• No specialist personnel required to operate the system

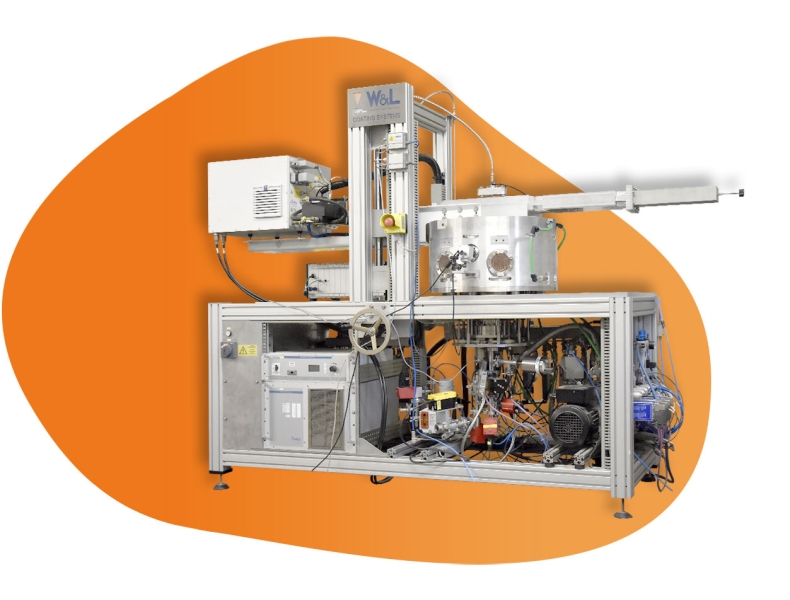

NMS 250

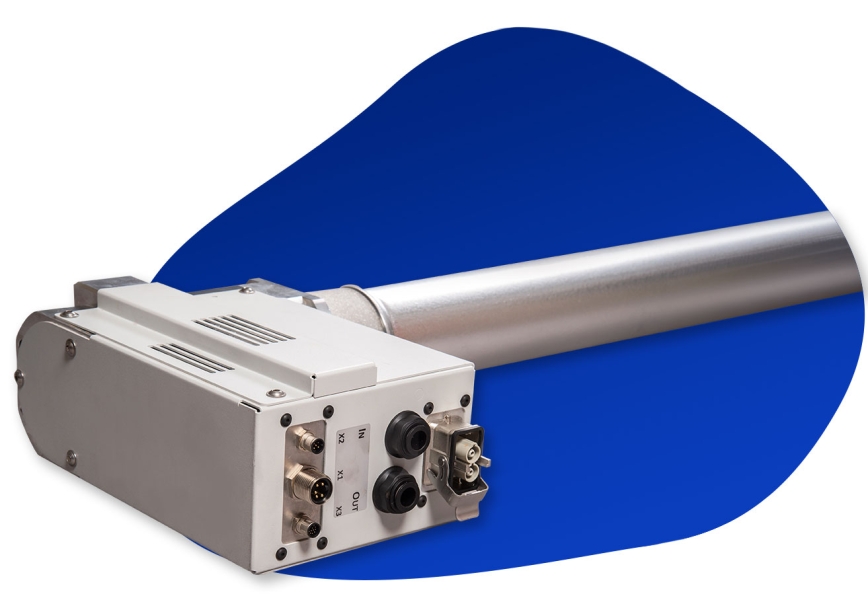

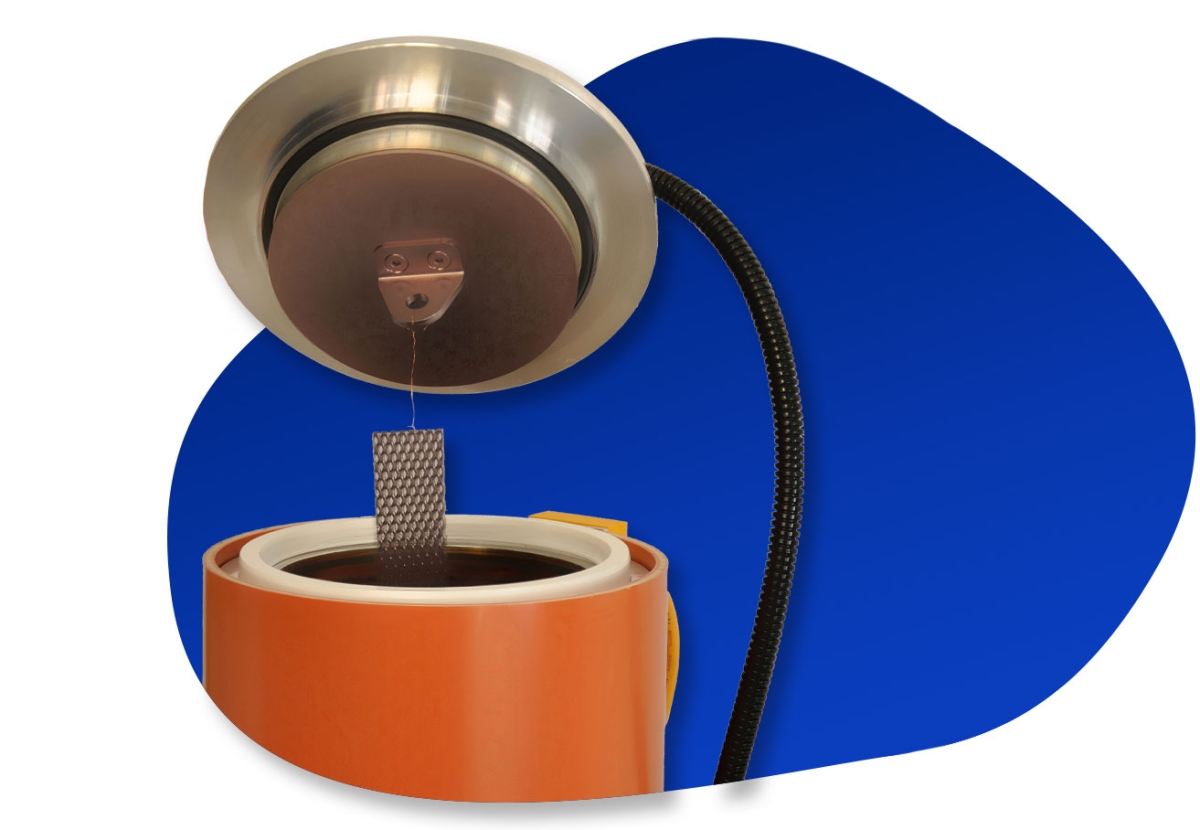

The NMS 250 coating system is suitable for sputtering individual parts or small series of 3D objects with a coating volume of ~200 mm in length and ~Ø 60 mm.

A compact and economical “desktop” magnetron sputtering system for precious metals. With a target length of 250 mm, suitable for coating individual parts. It takes less than 10 minutes from loading to igniting the plasma discharge. A target change can be carried out in a few seconds.

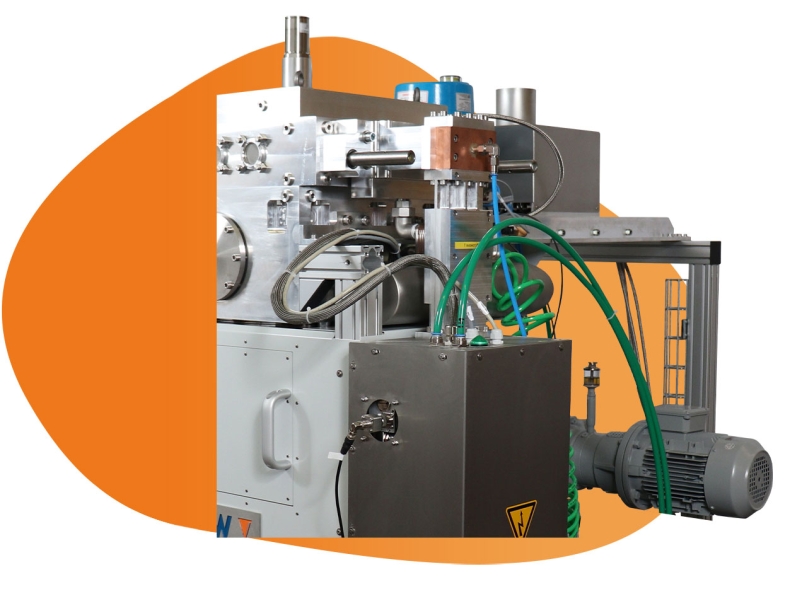

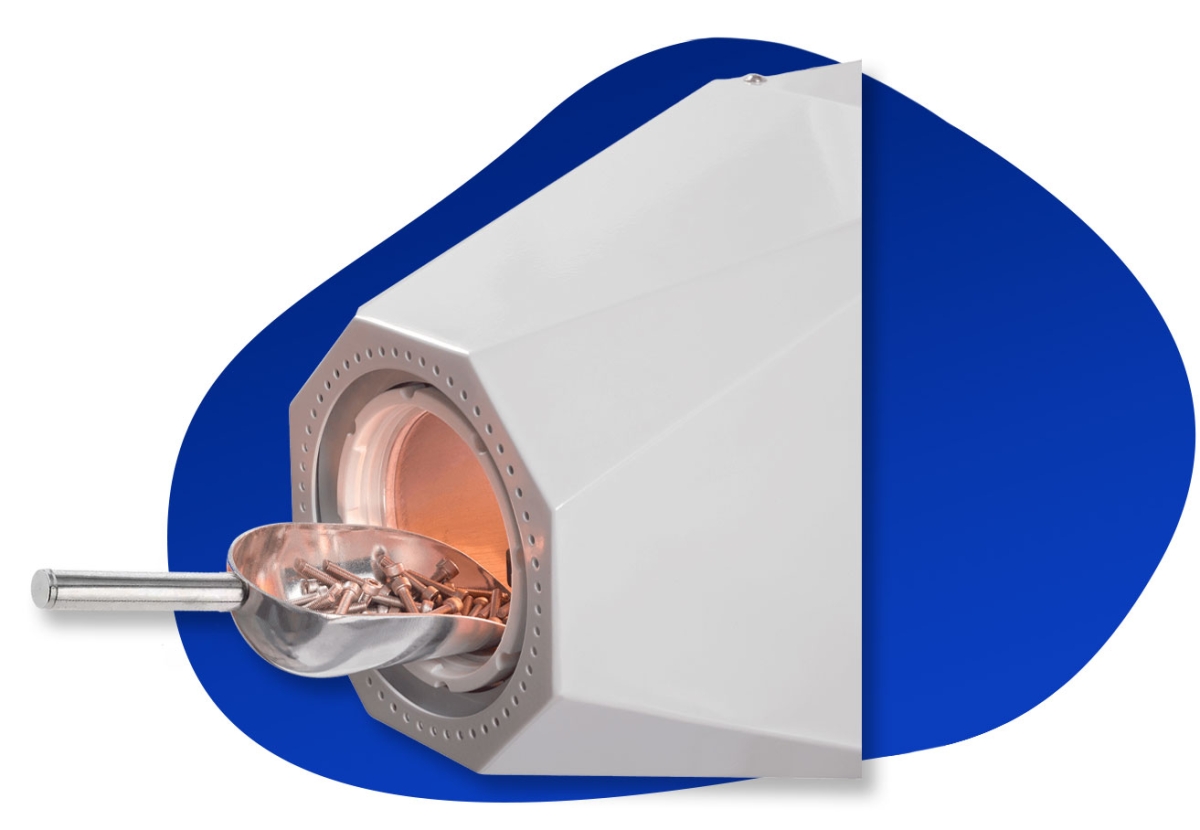

NMS-BM 270

small series sputtering of bulk materials

The NMS-BM 270 bulk material coating system is designed for sputtering small series of 3D objects with a total bulk material volume of up to 0.3 liters.

It takes less than 10 minutes from loading to igniting the plasma discharge. The coating rate is ~ 5 – 20 nm/min, depending on the material and process.

Everything you need

- let's get started

The compact table systems are equipped with all the necessary components for “stand-alone” operation and are ready for use in no time. You only need single-phase mains supply and process gas (argon). The systems have a programmable logic controller (PLC) with an integrated computer and a display for operation.

The systems' software can store and retrieve various process recipes. In these systems, the pumping speed of the membrane pump in combination with the turbomolecular pump (TMP) is relatively high compared to the chamber volume. This allows for a low vacuum base pressure and a fast pump down time, which is essential for high productivity. They are ideal platforms for economical and high-quality coatings for a wide range of functional and decorative applications. Specially developed for expensive coating materials, they are able to coat 3D objects without wastage. The NMS 250 and NMS-BM 270 are true “turn key” systems.